Data analysis based on data warehousing and business intelligence (BI) technology has not been applied.。

Business management layer。To establish and promote the business application system on the level of the Company。and now the management on the Company’s finance。customer and supplier has been realized.。

integration and business convergence of the system in use shall be further improved.。

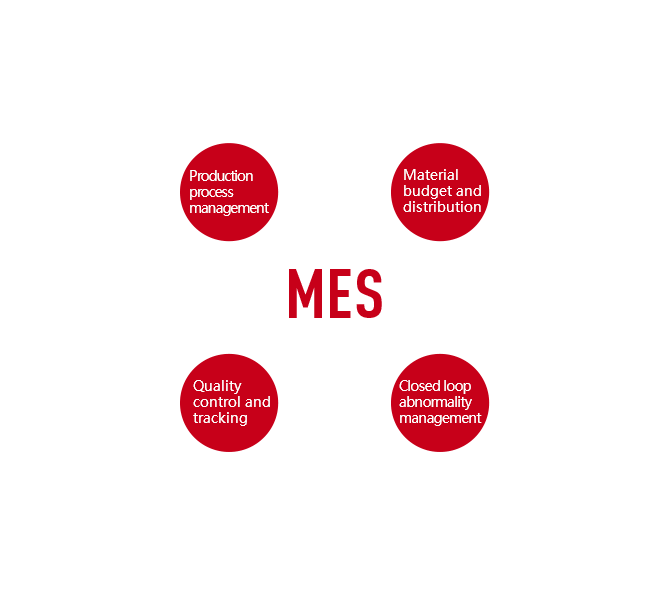

Through the five core systems of PLM, ERP, CRM, SCM and MES, to realize the intelligent, green and information management of the whole process including workshop equipment, production, personnel, quality, materials and environment and other aspects, so as to achieve the digitalization of manufacturing resources, of production process, of on-site operation, of quality management and of material management, as well as to achieve the aims of visualized production speed, real-time data collection, paperless production management and lean production logistics.

With electrification as the foundation and by integrating automatic drive and intelligent interconnection technologies, CRRC.EV offers a green intelligent traffic solution. As for the intelligent drive of the commercial vehicles, CRRC.EV will realize the demonstrative operation of L3 class intelligent drive as soon as possible, lot promotion at the end of the 13th 5-Year Plan period, and L4 class driverless driving in 2025.

As for intelligent interconnection, CRRC.EV will, based on the current Cloud System platform and by the cloud connection, cloud calculation and cloud intelligence, understand the users’ demands, actively offer services, connect 3 nets of human, vehicle and service, to give intelligence to vehicles, offer the ecological scenario services for end users and facilitate the transformation of the vehicles to the life spaces

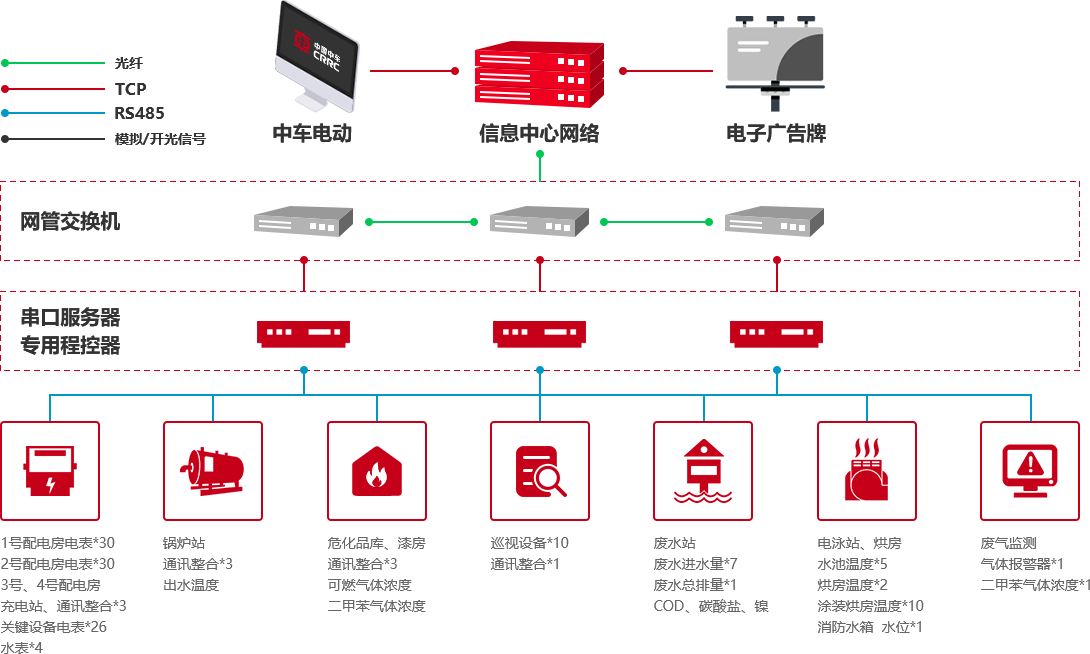

By online monitoring CRRC.EV’s energy consumption, to offer bases for the technical energy saving transformation and reduce the cost;

To improve the utilization of the key equipments and monitor their operation and management; to monitor the discharge and emission of CRRC.EV’s sewage and exhaust; to monitor CRRC.EV’s major hazards and safety inspection, and avoid any important or serious safety accident.